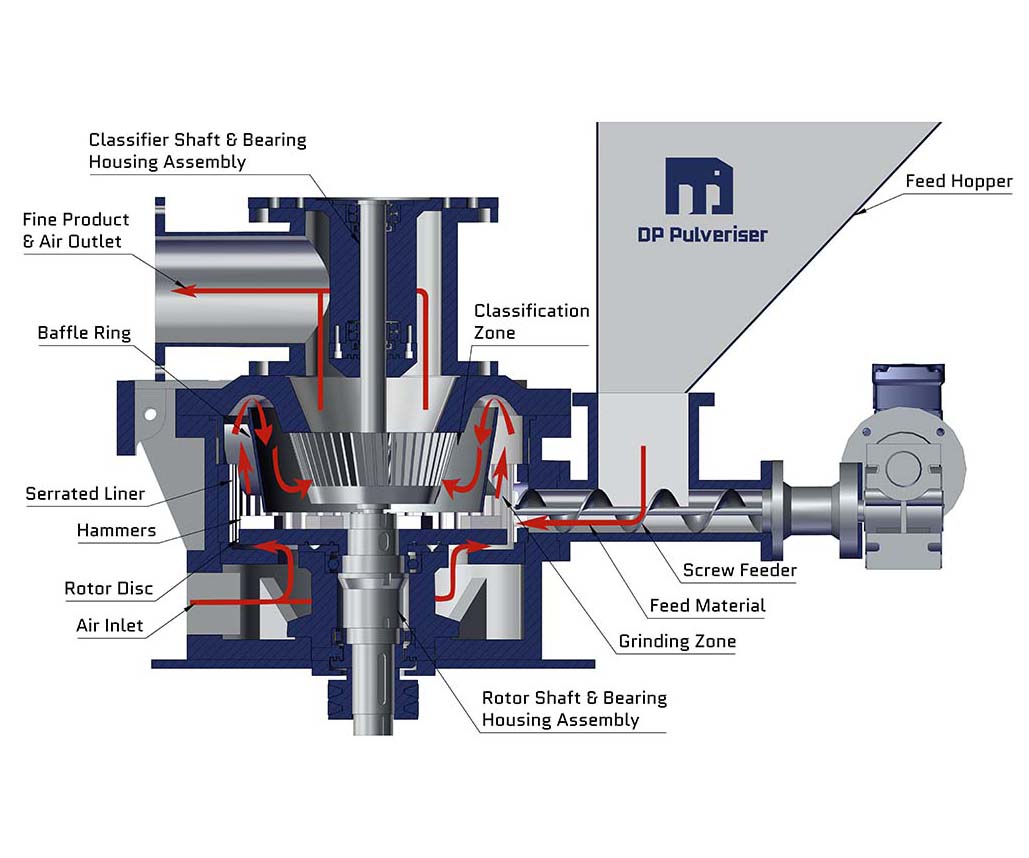

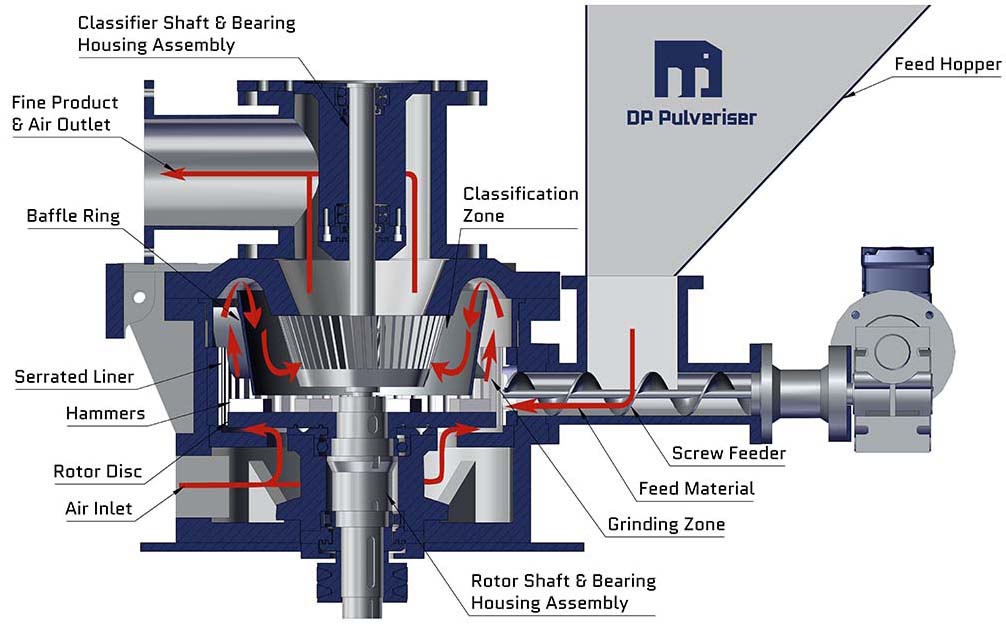

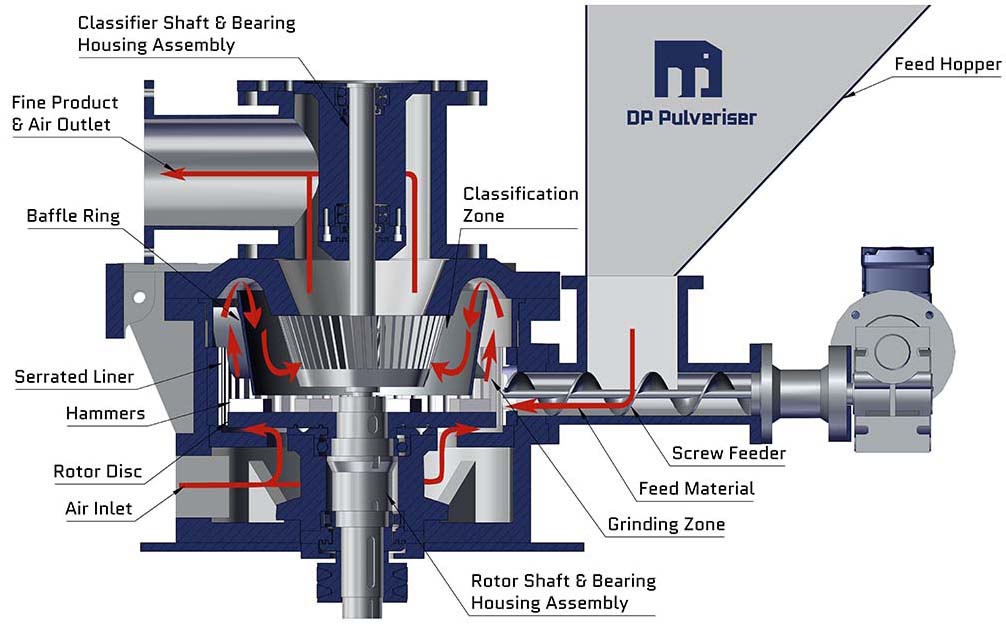

Working Principle

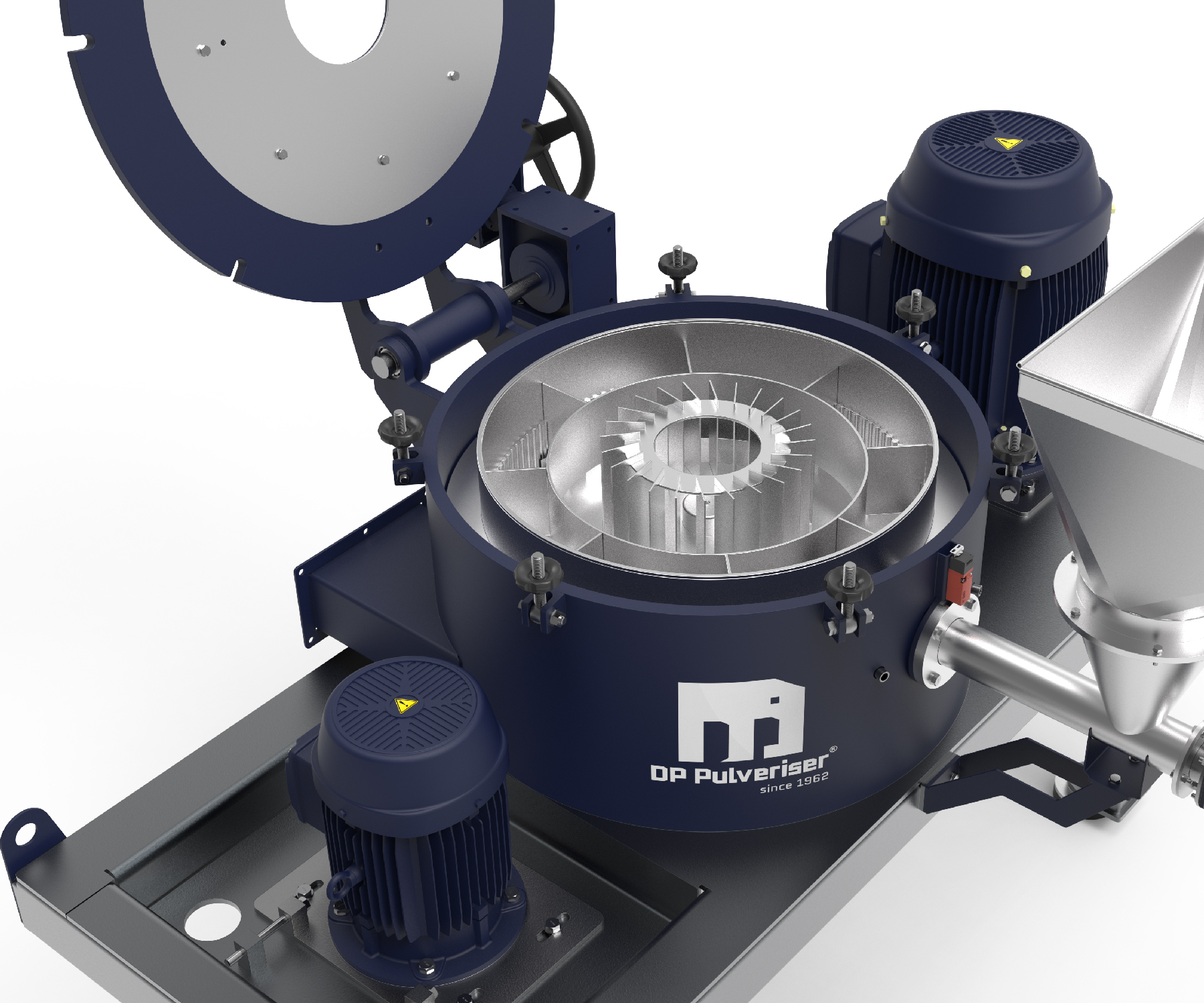

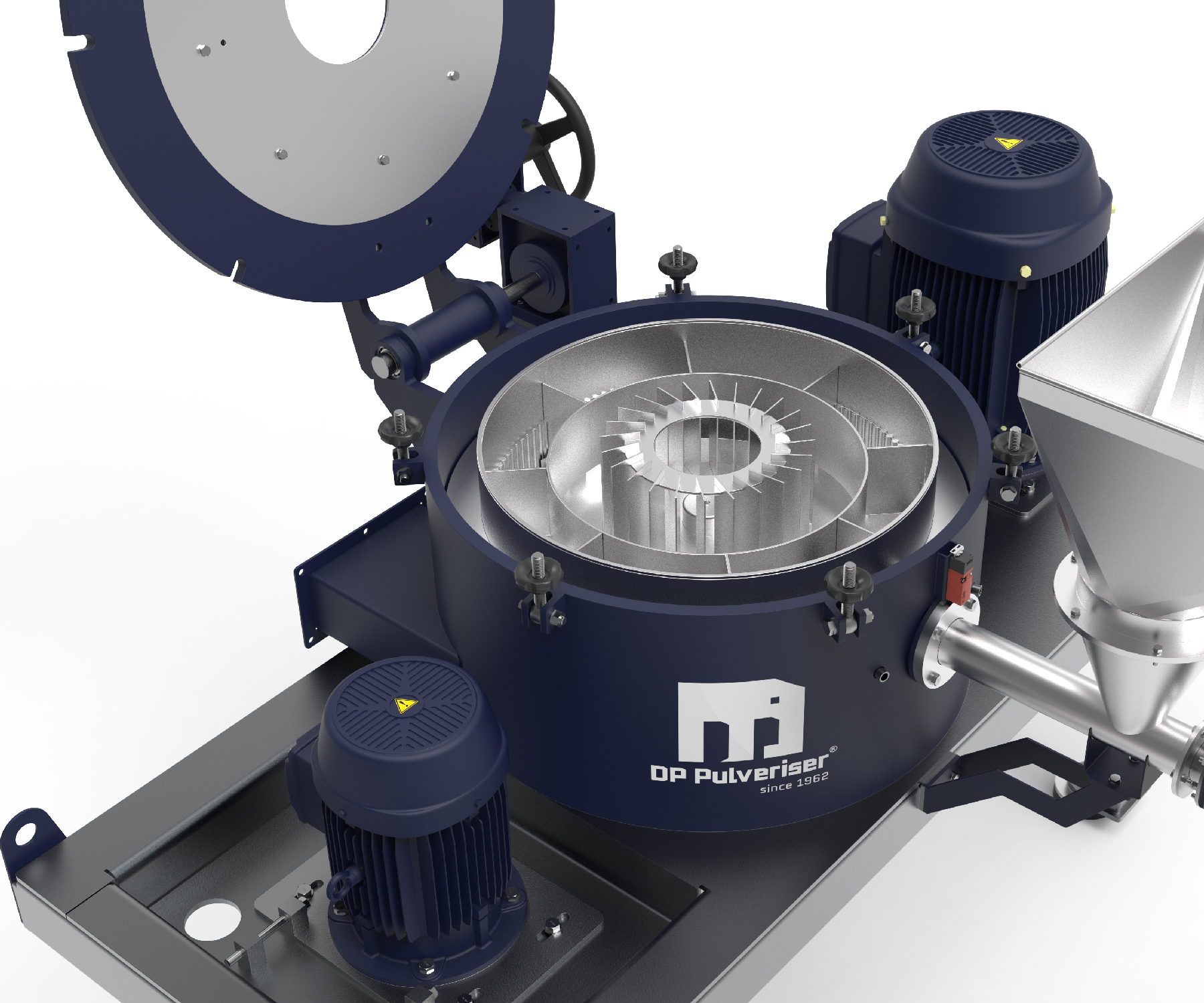

The DP® Air Classifier Mill integrates continuous grinding and dynamic classification into a single compact unit. The feed material enters through the Feed Hopper (1), where a Screw Feeder (2) delivers it at a regulated rate into the Grinding Zone (3). Inside this zone, a high-speed Rotor Disc (4) fitted with Hammers (5) accelerates the material outward. The Serrated Liner (6), positioned along the chamber wall, enhances impact by deflecting the material back into the hammer path, resulting in efficient size reduction through repeated collisions.

As the particles are ground, a stream of air introduced through the Air Inlet (7) assists in carrying the material upward into the Classification Zone (8). Here, the air/material mixture passes through a Baffle Ring (9) and reaches the rotating Classifier Rotor, housed within the Classifier Shaft & Bearing Housing Assembly (10). Particles of the desired size pass through the classifier and exit with the air stream via the Fine Product & Air Outlet (11), while oversized particles are rejected and returned to the grinding zone for further reduction. This internal loop ensures consistent fine product quality with a sharp particle size cutoff.

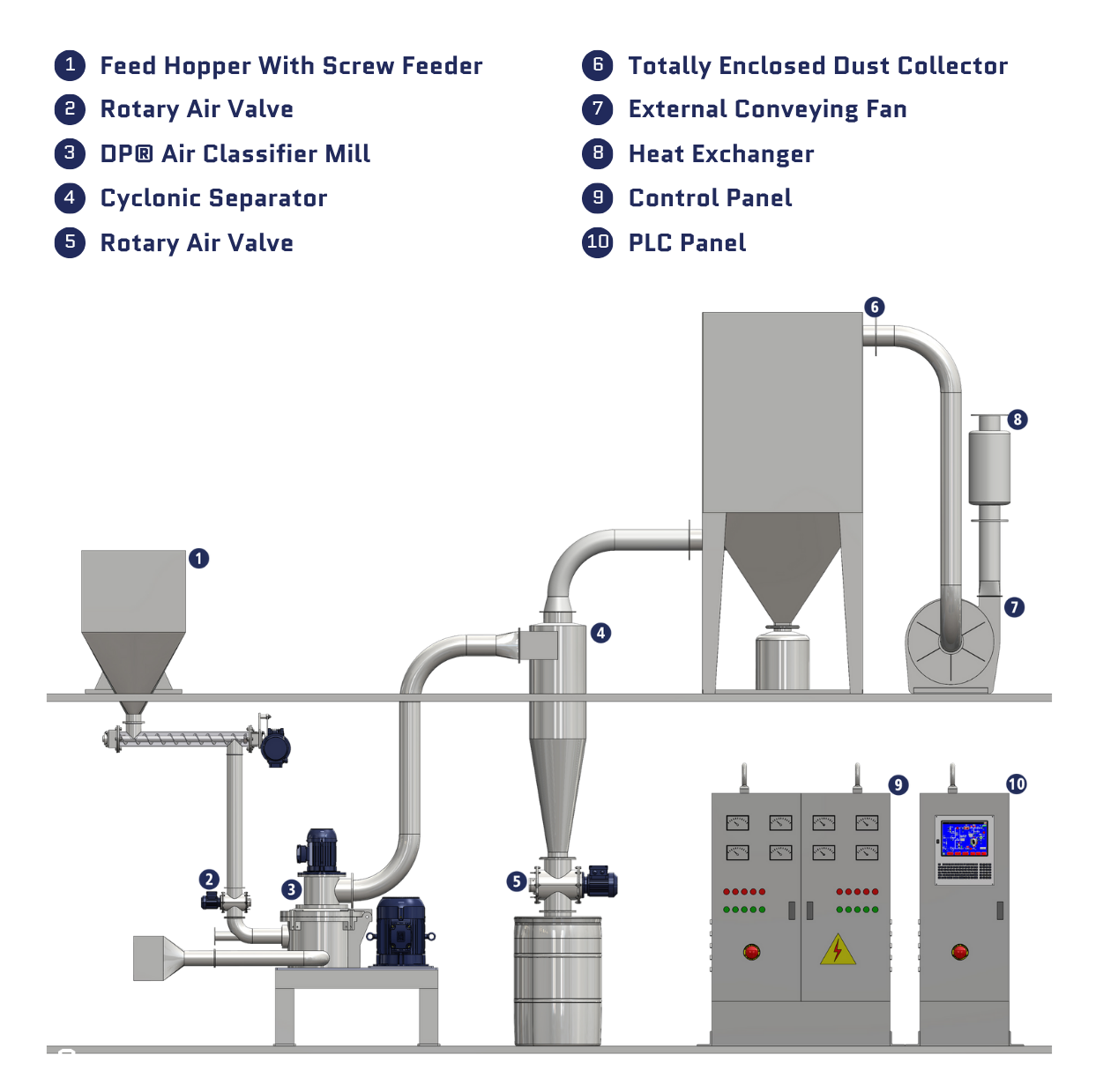

The mixture of fine product and air is then conveyed through external piping to a cyclonic separator, where the product is separated and collected. Any remaining ultrafine dust is carried further to a pulse-jet dust collector, ensuring clean and dust-free air discharge. The system also include a conveying blower to maintain controlled airflow. Overall, the integrated design allows for precise particle size control, energy-efficient grinding, and dust-free operation in a compact and maintainable layout.

Features & Benefits

- Integrated grinding and dynamic classification in one compact unit

- High-speed rotor with impact hammers or pins

- Stepless easy online particle size adjustment and control

- Narrow particle size distribution

- Suitable for fine and ultrafine particle size up to 8 microns

- Serrated liner for enhanced grinding efficiency

- Suitable for combined grinding and drying