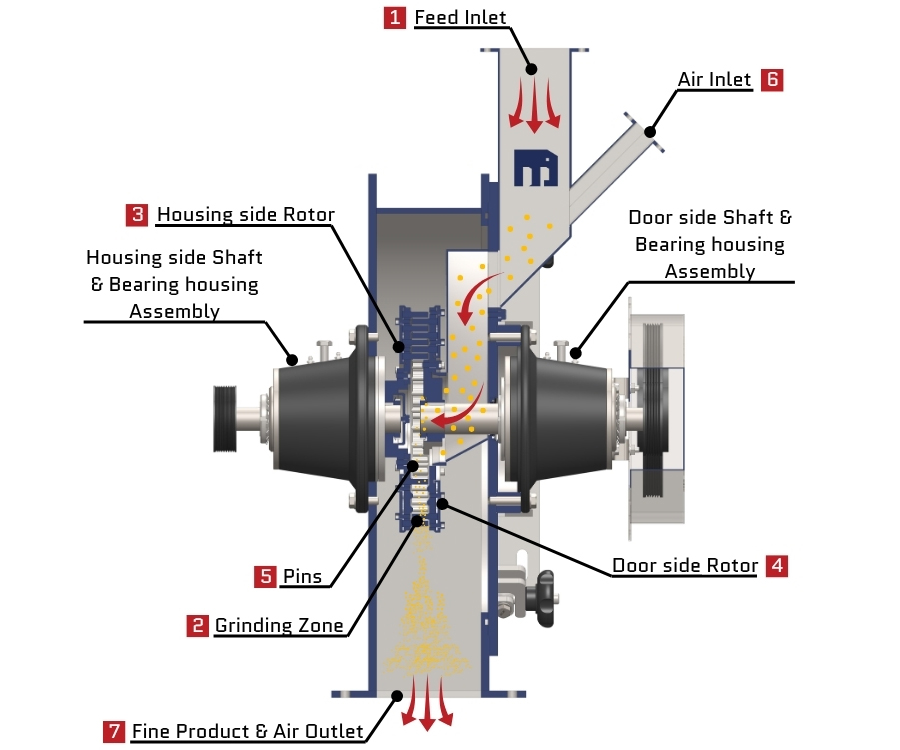

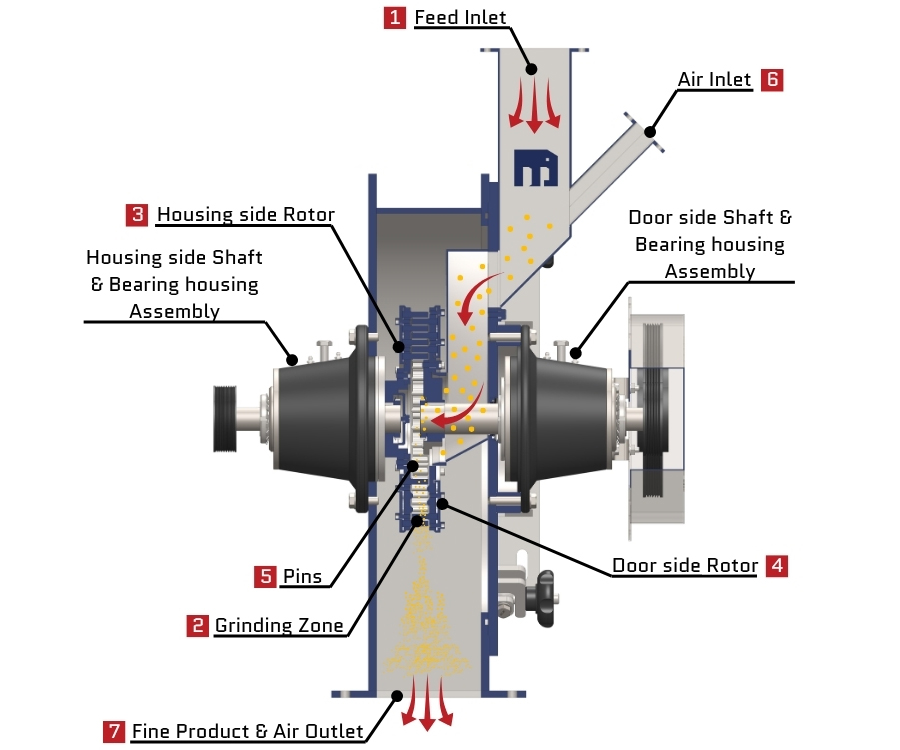

Working Principle

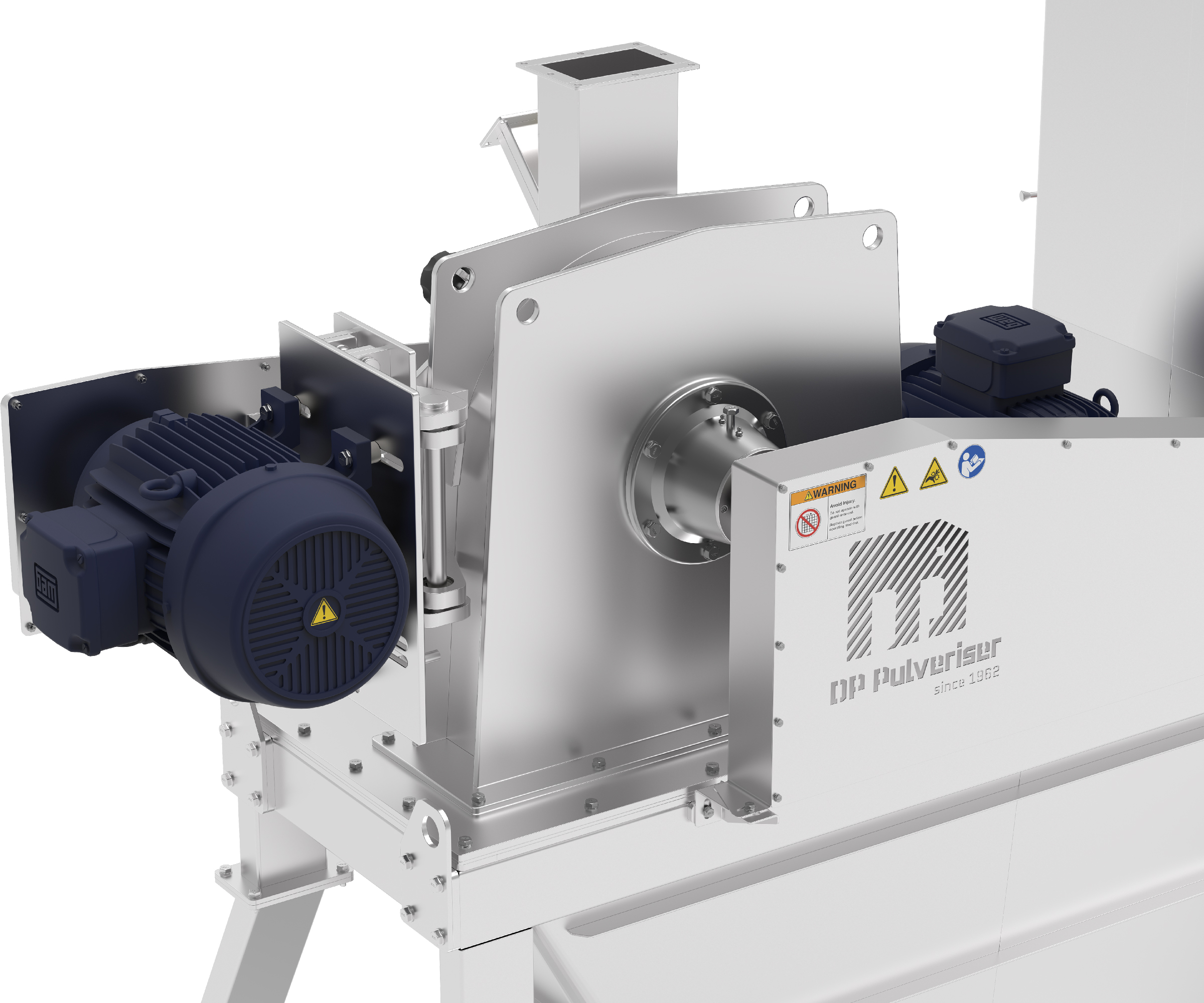

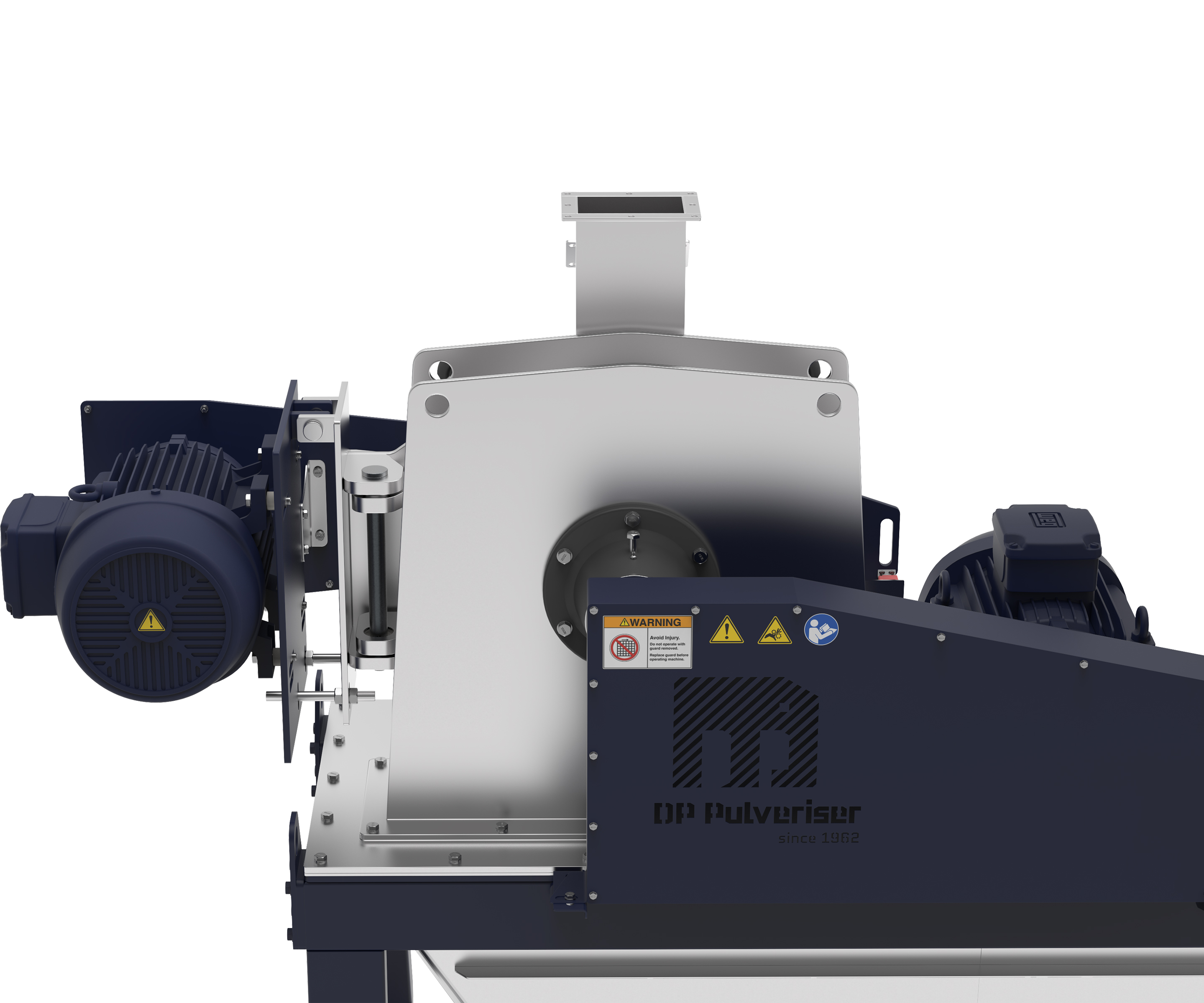

The DP® CONTRA Pin Mill is designed for efficient ultra-fine grinding using two contra-rotating pin discs. Material enters through the feed inlet(1) and is directed into the grinding zone(2) with the aid of controlled feeding systems such as a screw or vibratory feeder. Simultaneously, air is introduced through the air inlet(6) to assist in transporting and fluidizing the material.

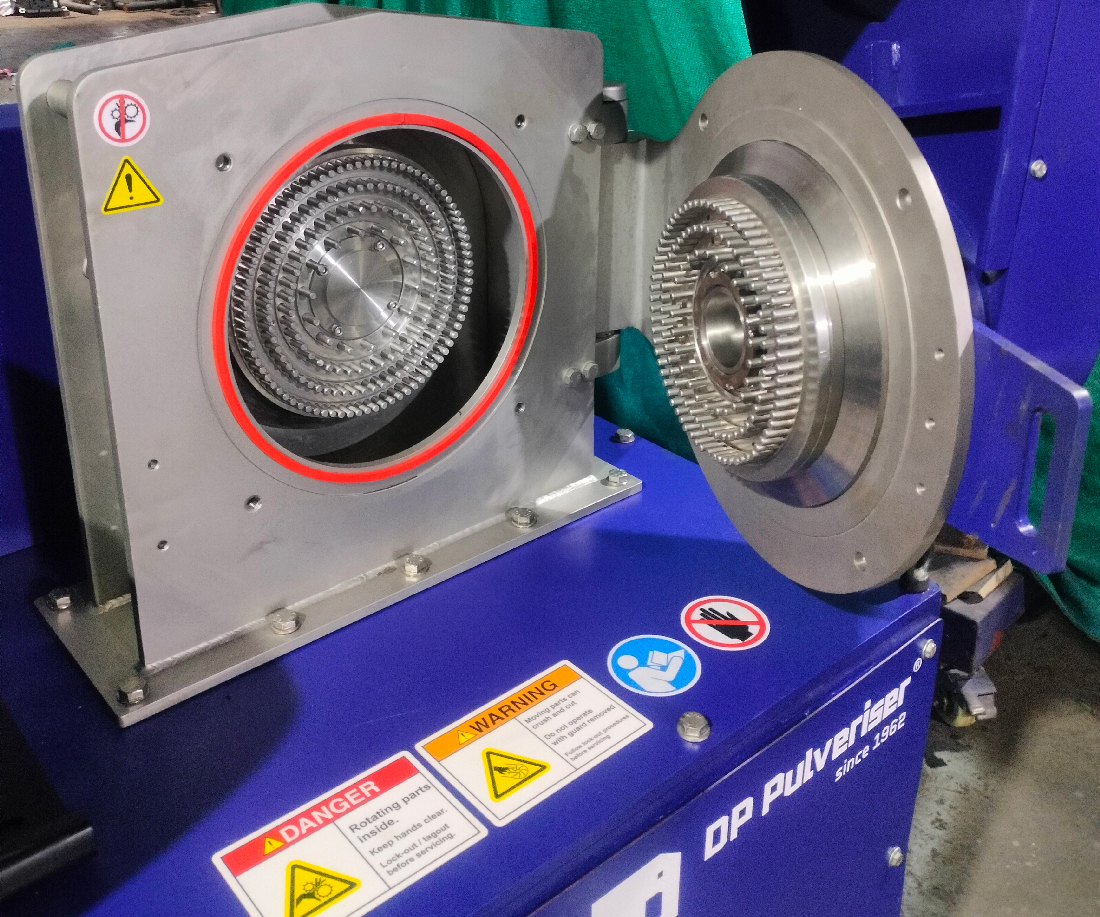

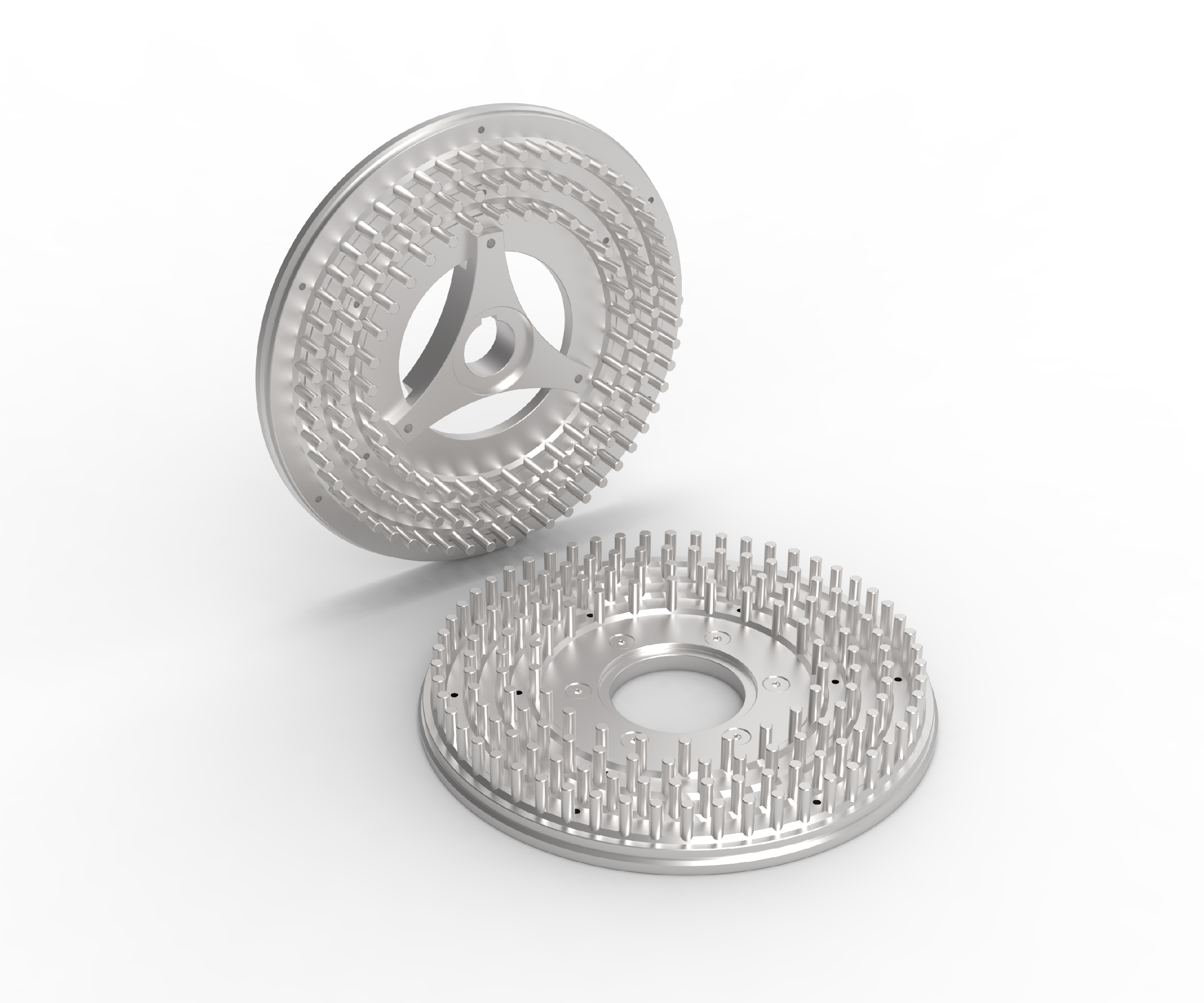

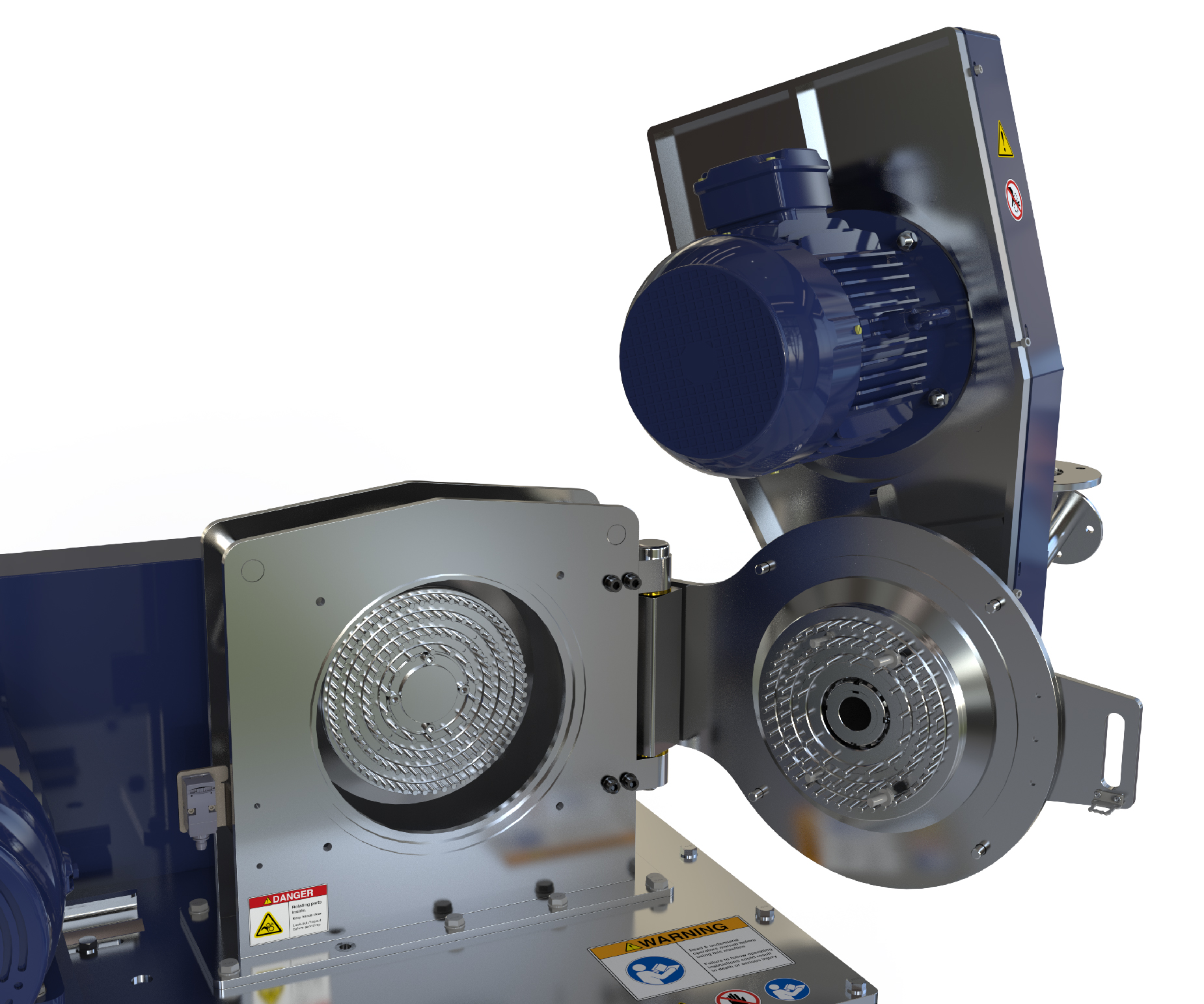

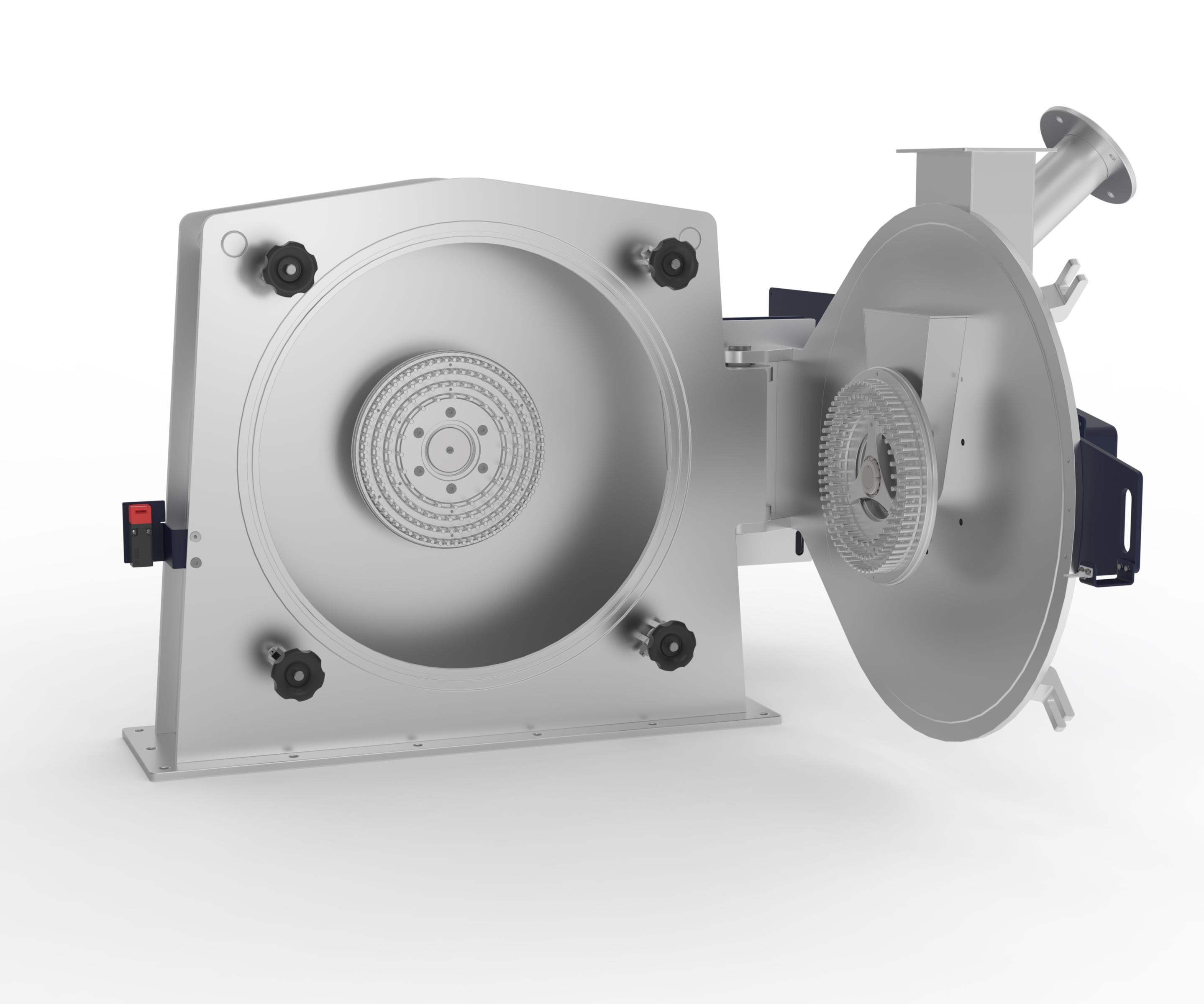

At the heart of the mill are two precision engineered rotors the housing side rotor(3) and the door side rotor(4) each equipped with intermeshing pins(5). These rotors spin in opposite direction, generating a maximum relative tip speed of up to 250 m/s. This high speed counter rotation create intense impact and shear forces, resulting in rapid deagglomeration and efficient particle size reduction.

This mechanism is particularly well-suited for brittle, crystalline, greasy, or heat-sensitive materials, delivering fine grinding without the need for screens. After size reduction, the fine product exits the chamber via the fine product & air outlet(7) and can be collected or pneumatically conveyed as per process requirements. The fineness can be easily adjusted by controlling the rotational speed and configuration of the pin discs.

Features & Benefits

- High grinding fineness with low specific energy consumption

- Intensive, agglomerate free and homogeneous mixing grinding of products

- Dual driven pin discs for achieving high fineness values in the range of approx. 10 to 500 µm

- Individual setting of the grinding parameters - speed, direction of rotation, etc

- High relative disc speed up to 250 m/s enables superior fineness, especially for brittle and crystalline materials

- Hassle-free operation with our screenless design, eliminating common issues associated with traditional screening method