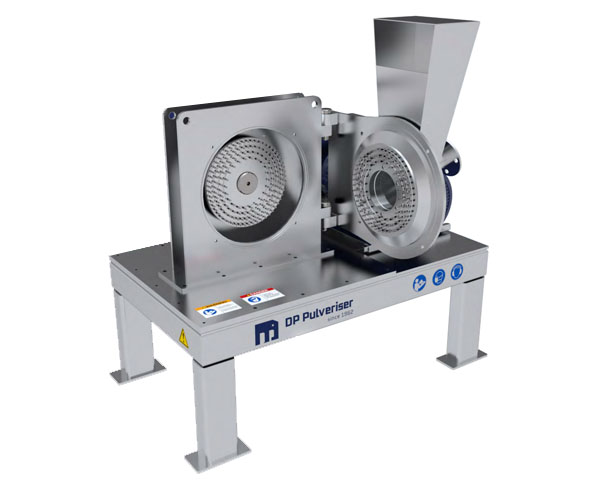

Working Principle

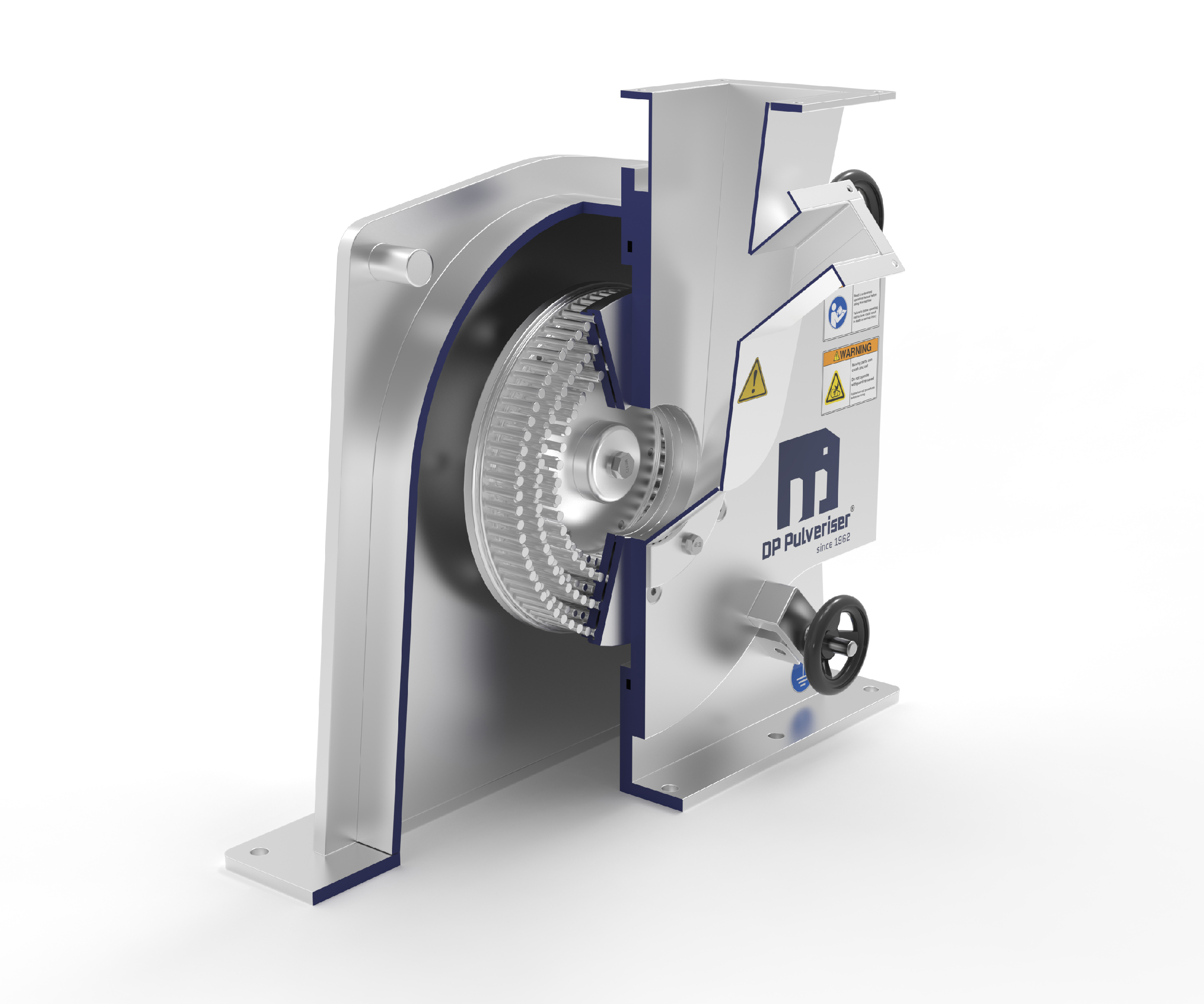

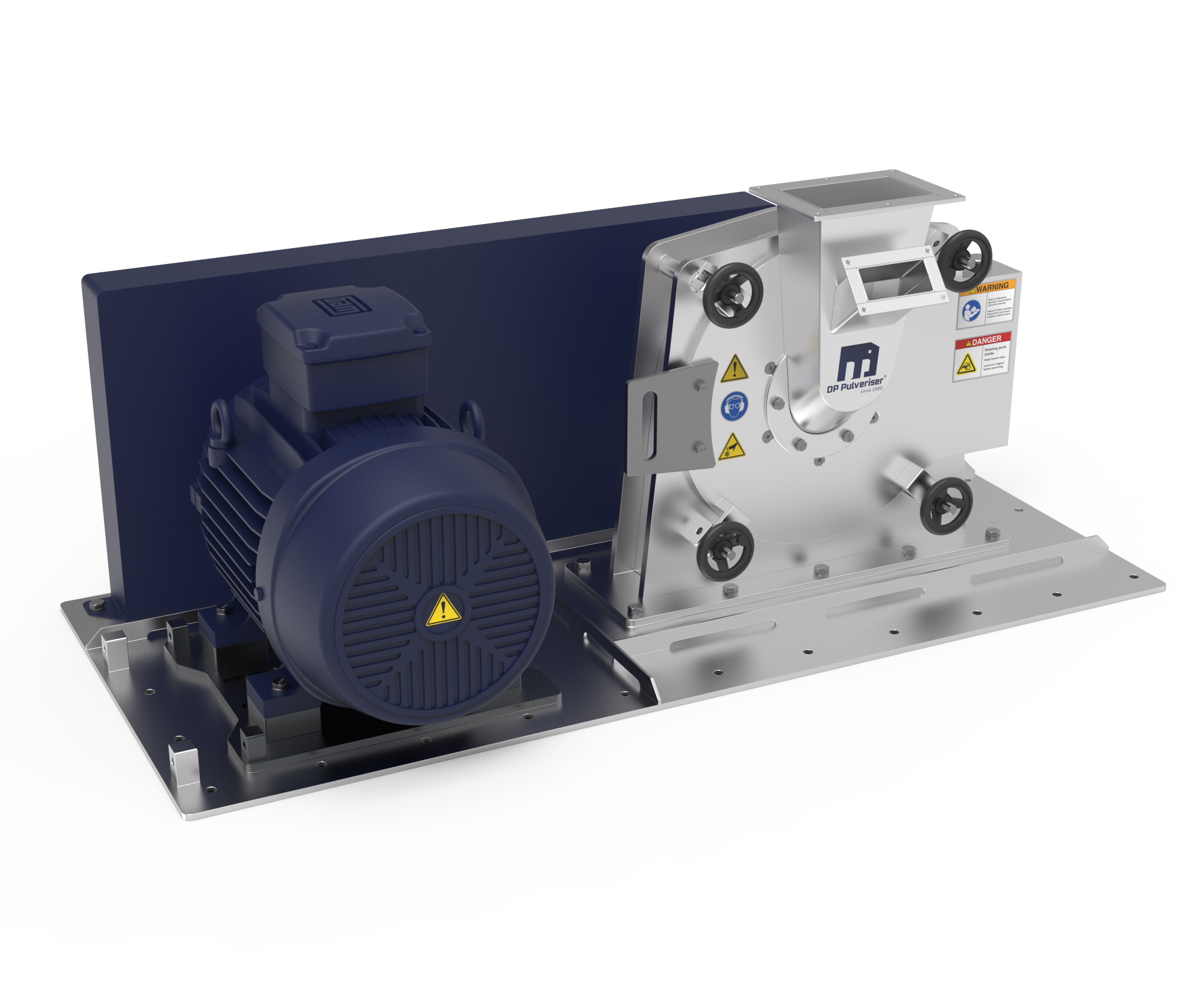

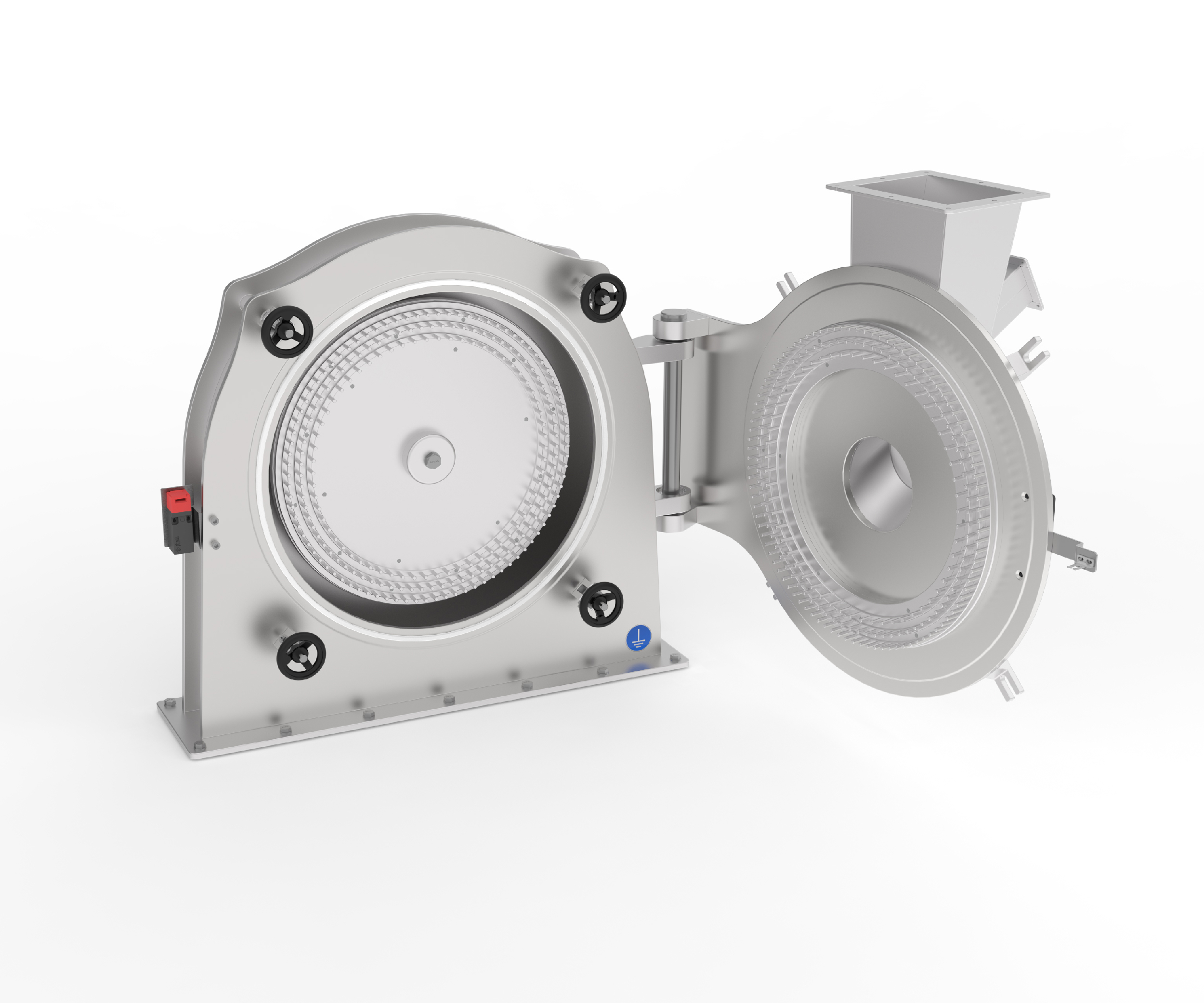

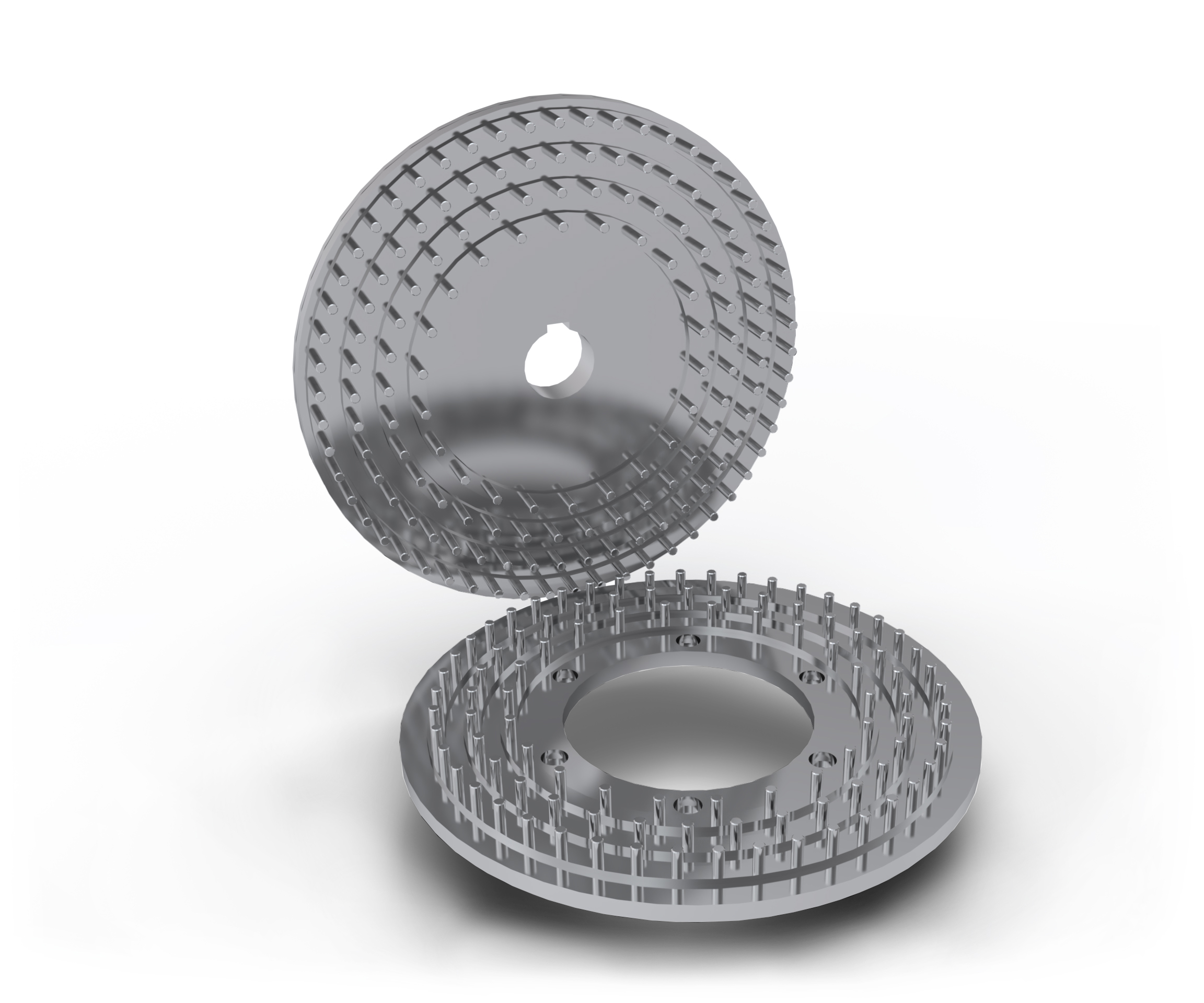

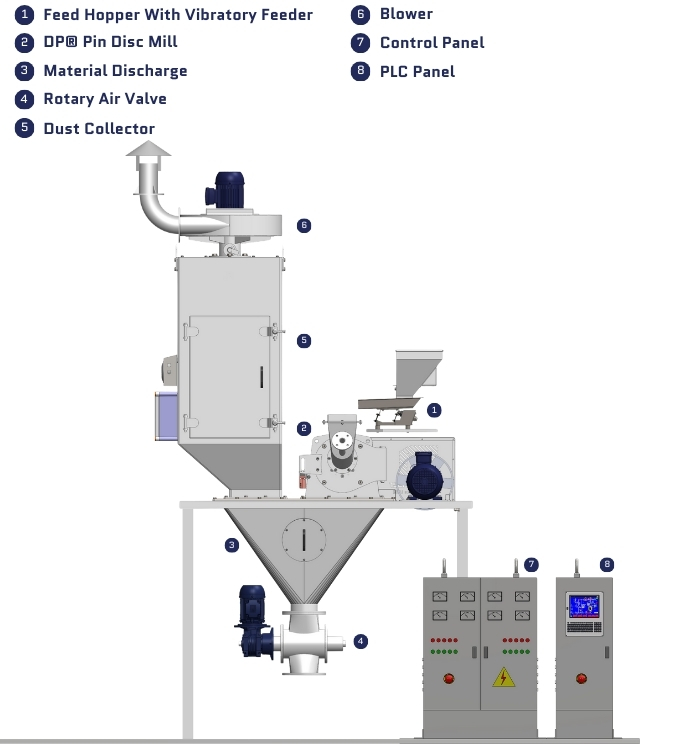

The DP® Pin Disc Mill operates on the principle of high-speed impact between two pin discs—one rotating and one stationary. Material enters through the feed inlet (1) and is directed into the grinding zone (2) by gravity or controlled feeding systems such as a screw or vibratory feeder. Air can be introduced via the air inlet (6) to aid material transport, cooling, and fluidization during milling.

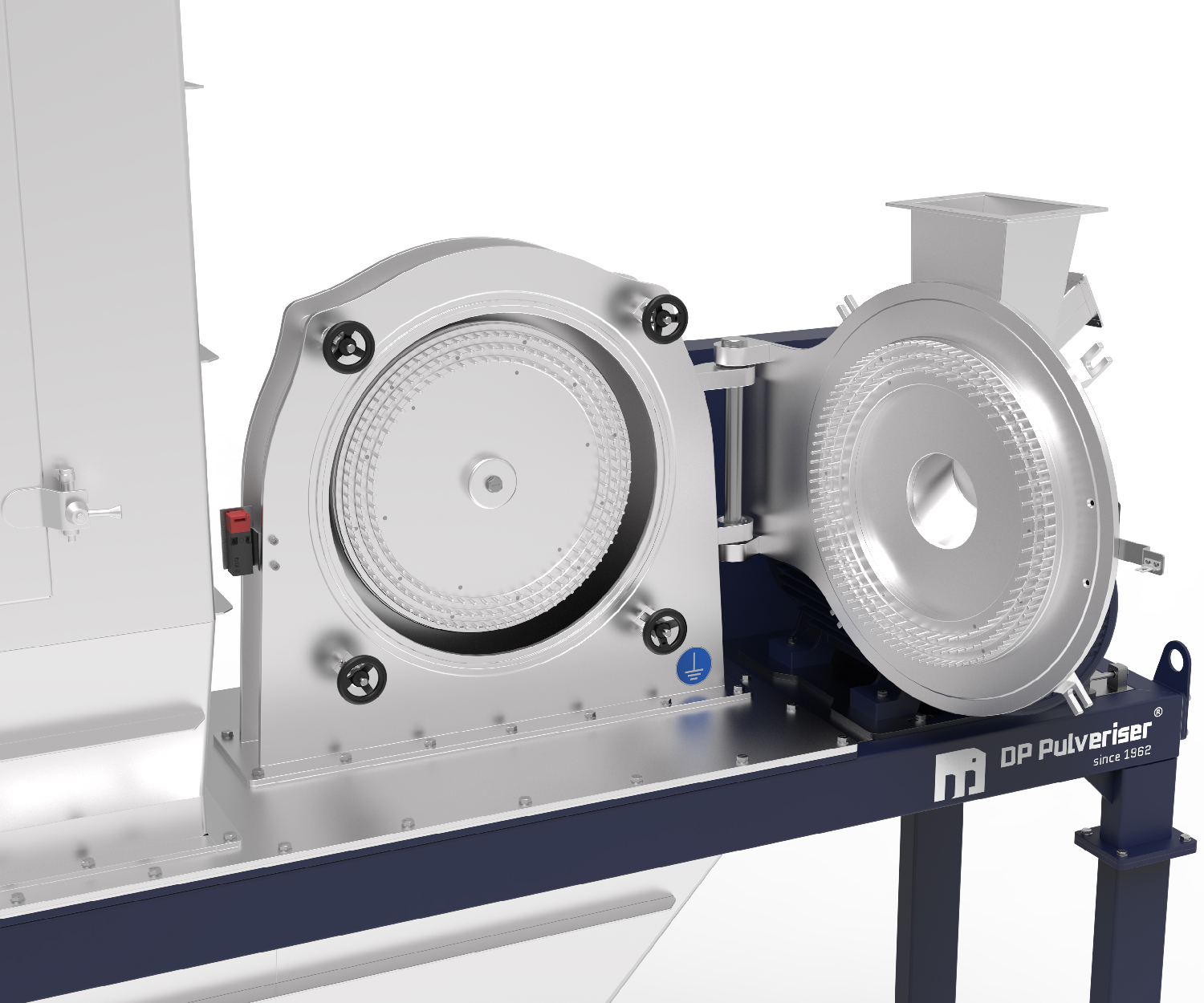

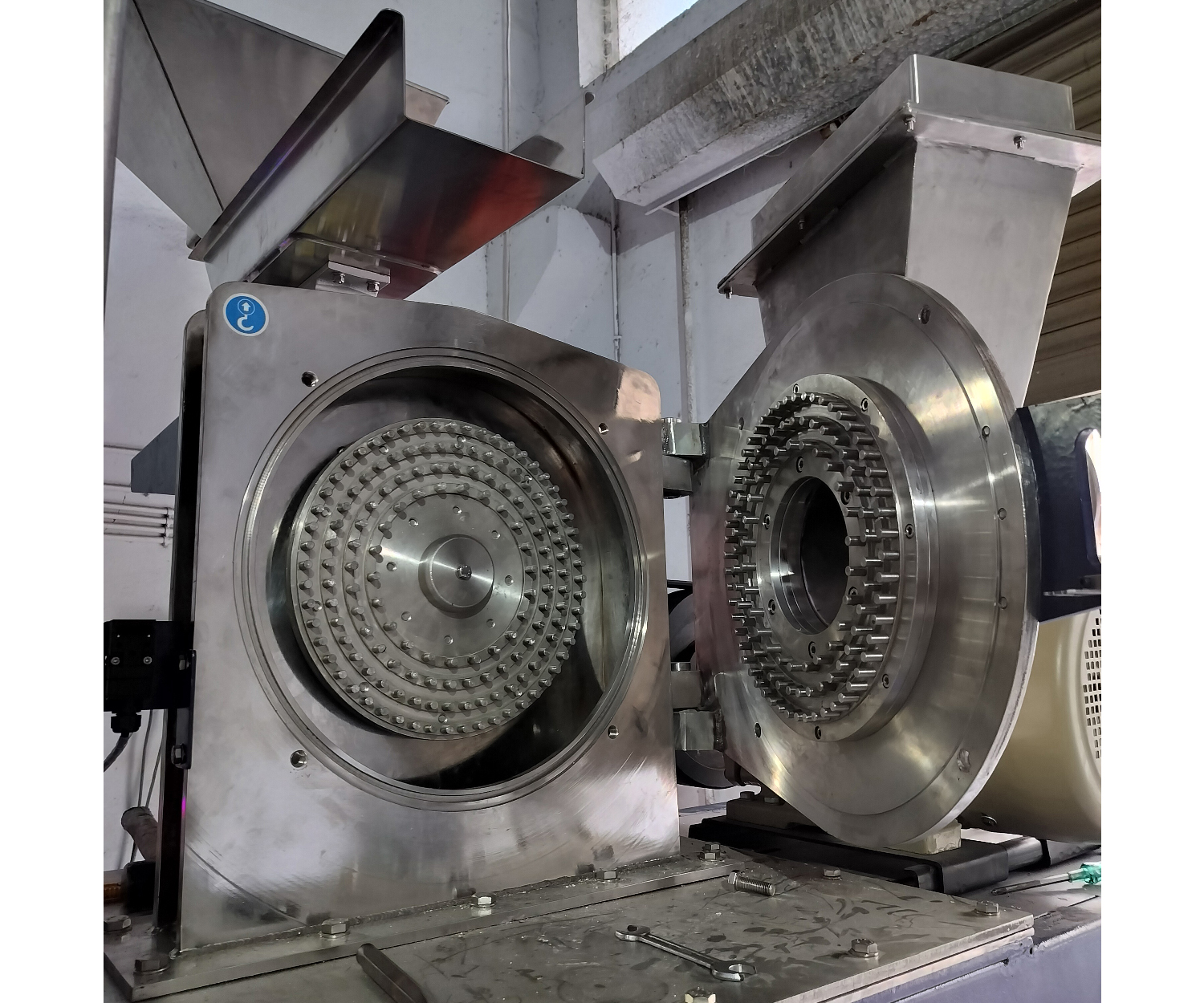

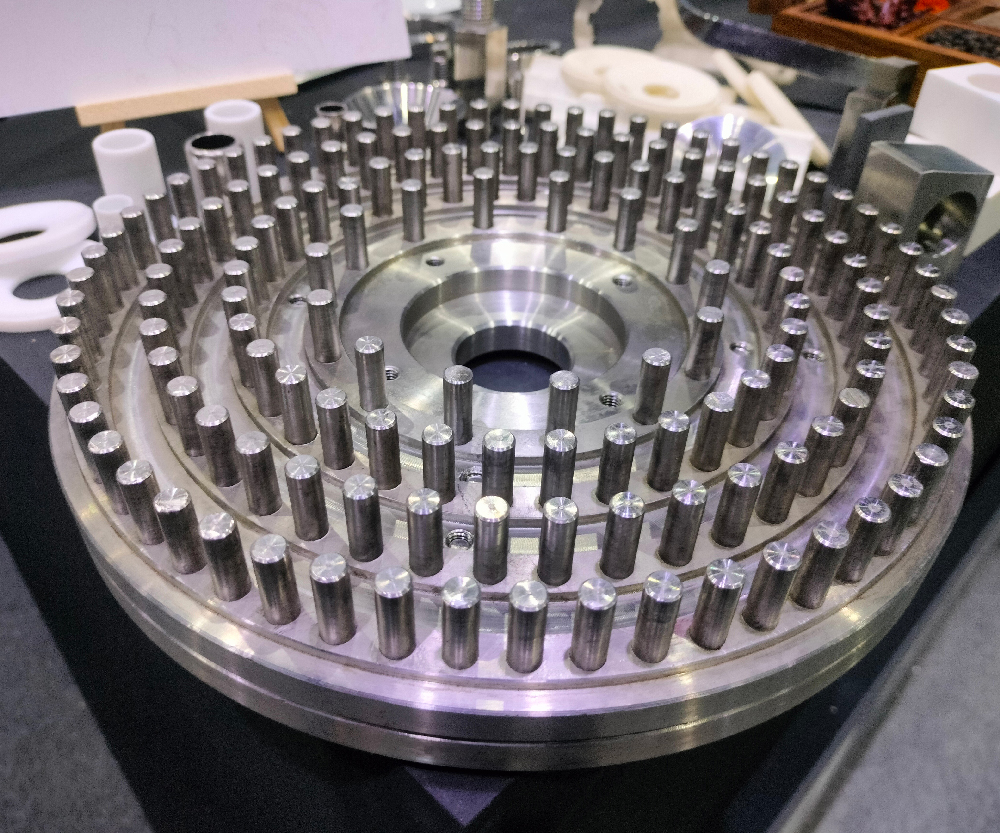

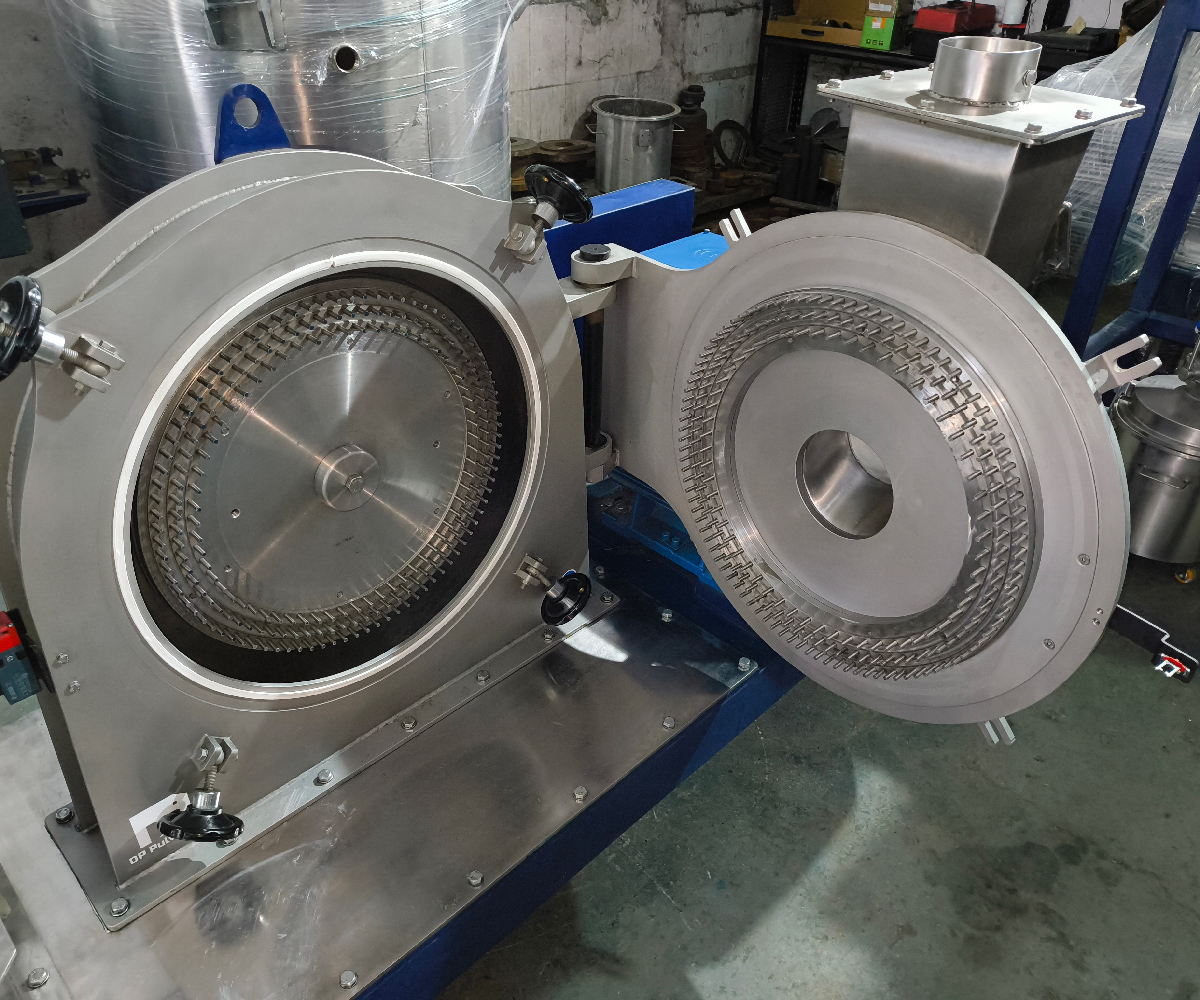

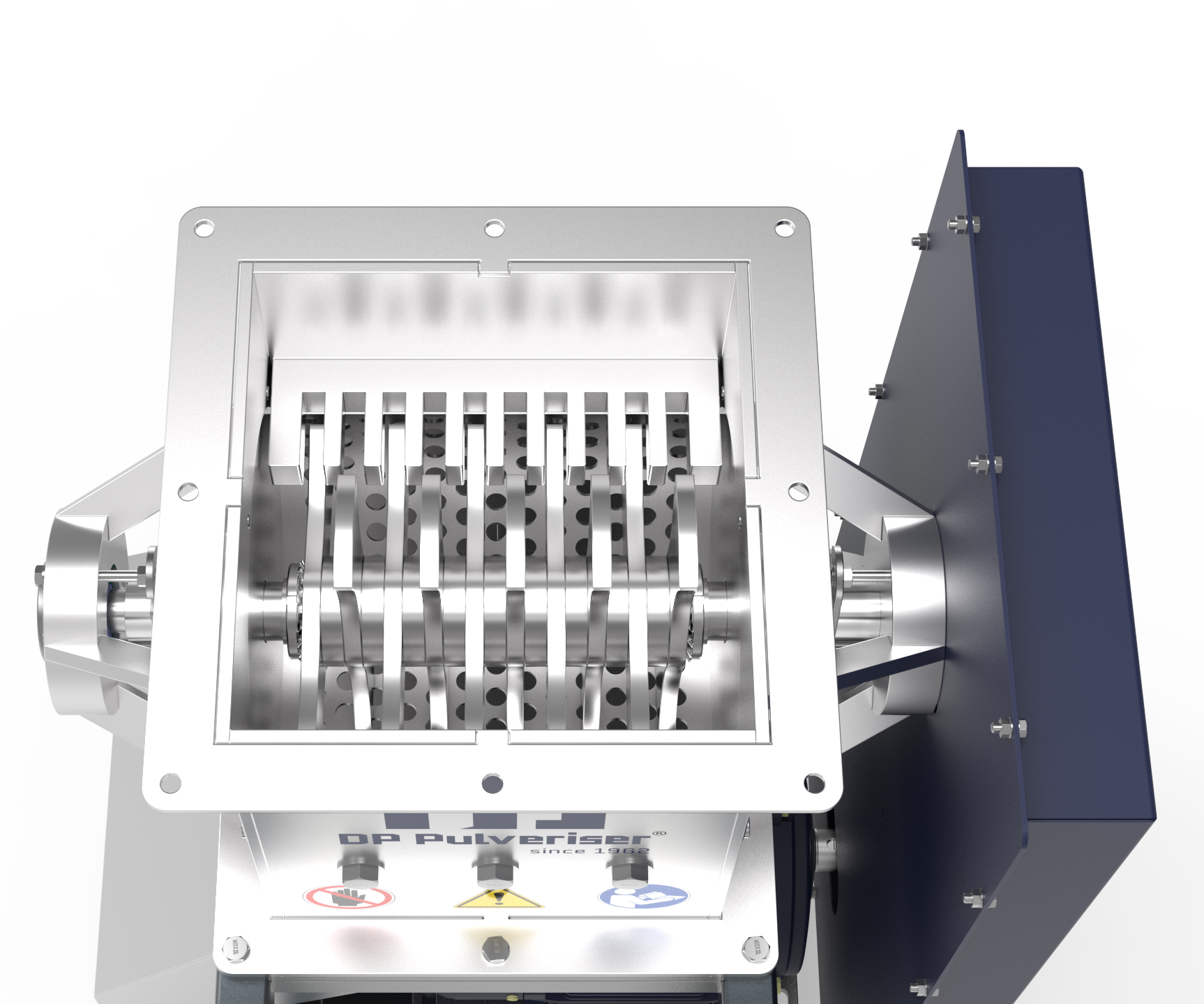

Inside the grinding chamber, the housing side rotor (3) and the door side stator (4) are equipped with precisely arranged pins (5). As the rotor spins at high speed, particles are accelerated and collide repeatedly with the stationary pins, as well as with each other. These high-energy collisions result in rapid size reduction without the use of screens.

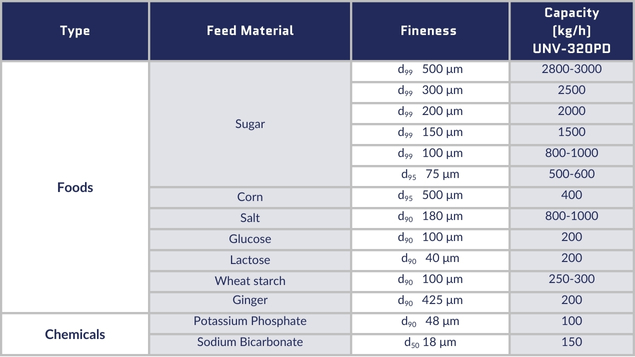

This configuration is ideal for crystalline, brittle, and low-oil content materials, producing consistent, uniform fineness. The final product, along with process air, exits via the fine product & air outlet (7) for collection or pneumatic conveying. Particle size can be adjusted by varying rotor speed, pin configuration, and feed rate to meet specific application requirements.

Features & Benefits

- Achieves particle sizes down to 35 µm for precision applications

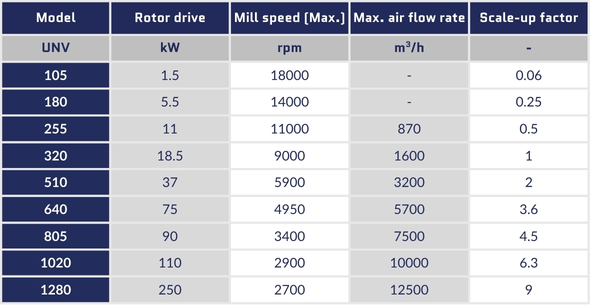

- Available in laboratory and production models to suit R&D or high-capacity needs

- Capable of processing materials up to Mohs hardness 4 or less

- Variable speed rotor drive for precise control of fineness and throughput

- Operates efficiently with low energy consumption and reduced operating costs

- Delivers uninterrupted grinding with a screen-fre design, ensuring consistent output and minimal downtime

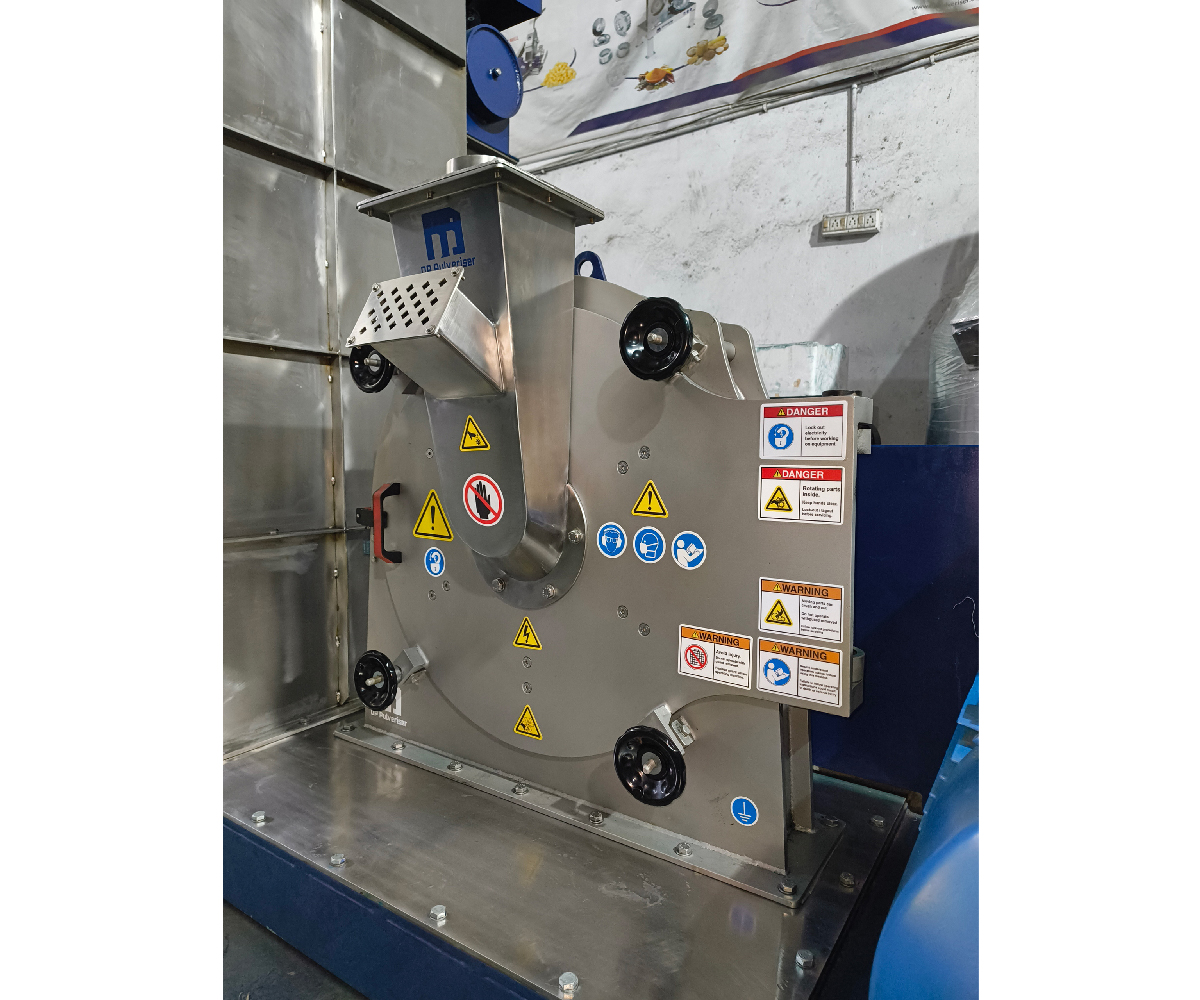

- Grinding chamber and components designed for easy access and quick cleaning