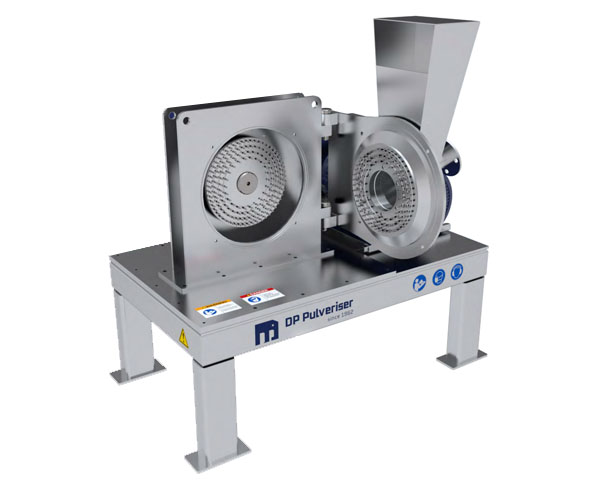

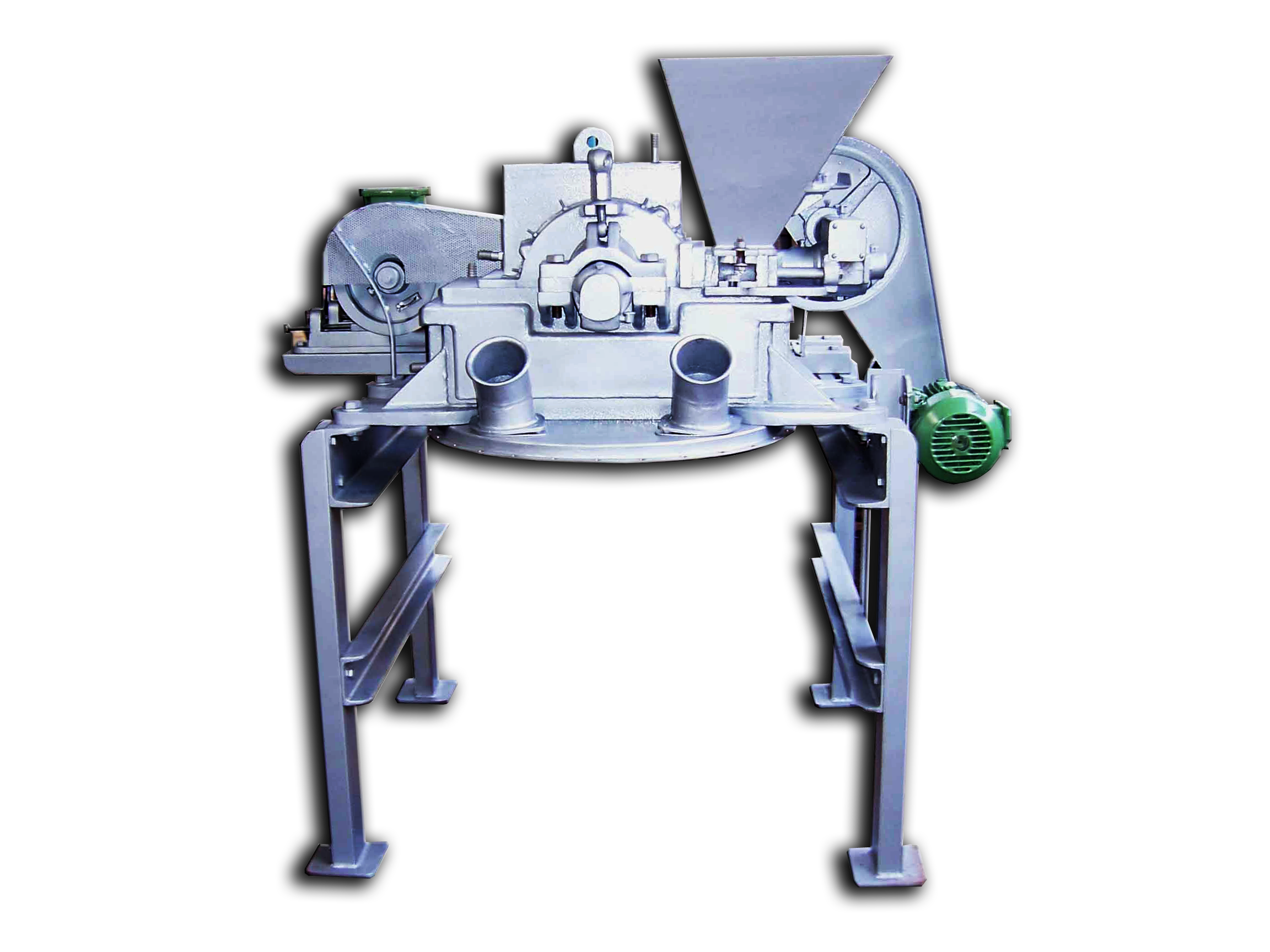

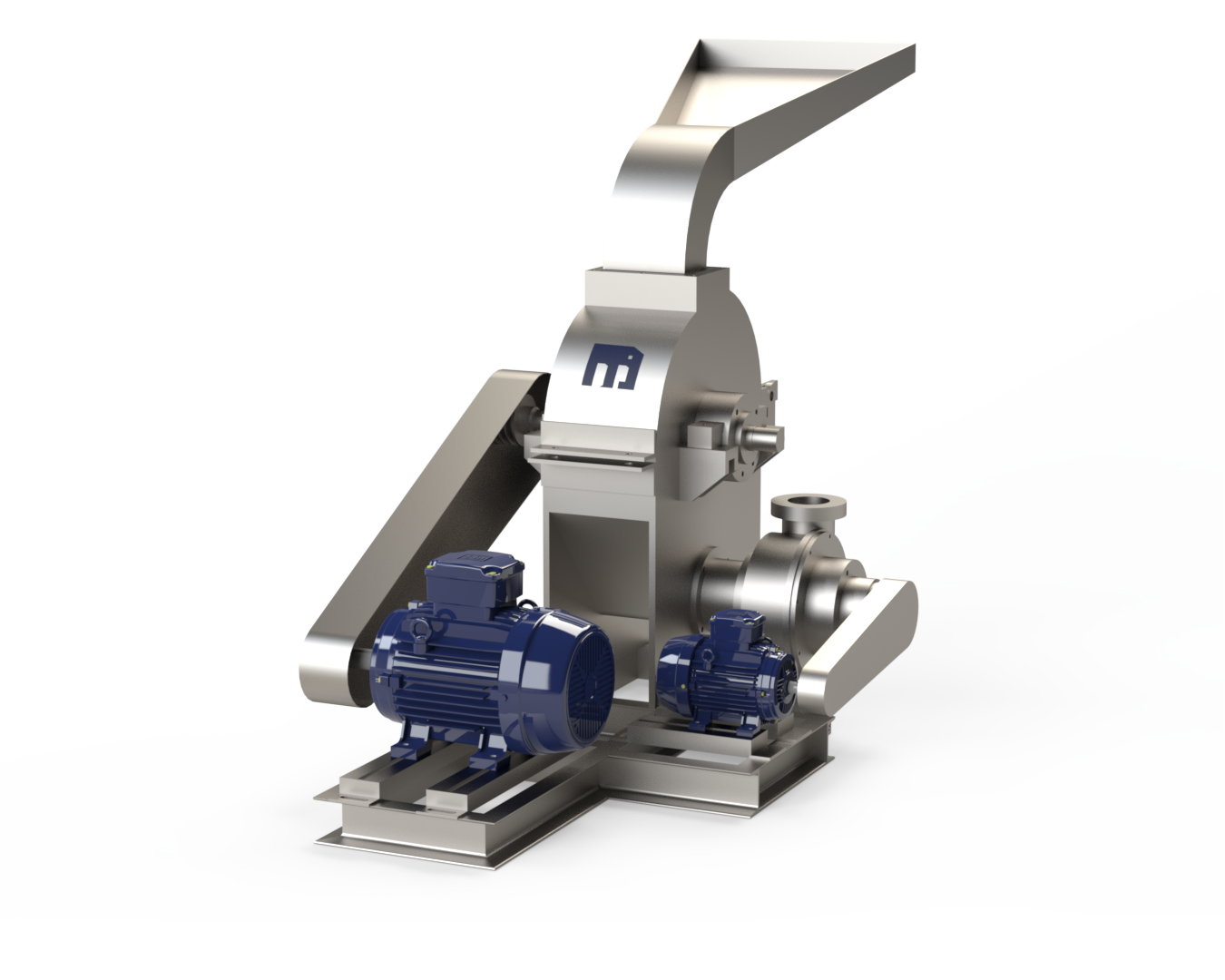

DP® UNIVA Pin Mill

DP® UNIVA Series Pin Mill is a specialized grinding machine that uses circular steel pins that interlock to efficiently crush or grind different materials into fine particles. Feed material is fed into the milling chamber. Inside the mill, there's a rotor equipped with closely spaced pins. These pins rapidly spin around their axis. As the rotor spins the particles collide with the rotating pins. This collision causes the particles to break and grind into smaller sizes, the centrifugal force generated by the spinning rotor helps to propel the ground particles through the screen, The milling process is adjustable, allowing for control over the fineness of the end product.

Constructed from durable stainless steel, it can

grind materials with a hardness level of up to 4, thanks to its

adjustable-speed rotor. The machine's compact design ensures easy accessibility

for cleaning, minimizing operational mess and providing a seamless and

efficient grinding experience.

- Allowable Feed Size: <10 mm

- Achievable Output Fineness: 50 micron

- Throughput Capacity: 4 TPH