Working Principle

The DP® Bar Turbo Mill operates on the principle of high-speed impact and shearing between rotor-mounted bars and a fixed liner. Material enters through the feed inlet (1) and is directed into the grinding zone (2) by gravity or controlled feeding systems such as a screw or vibratory feeder. Air can be introduced via the air inlet (6) to assist in material transport, cooling, and fluidization during milling.

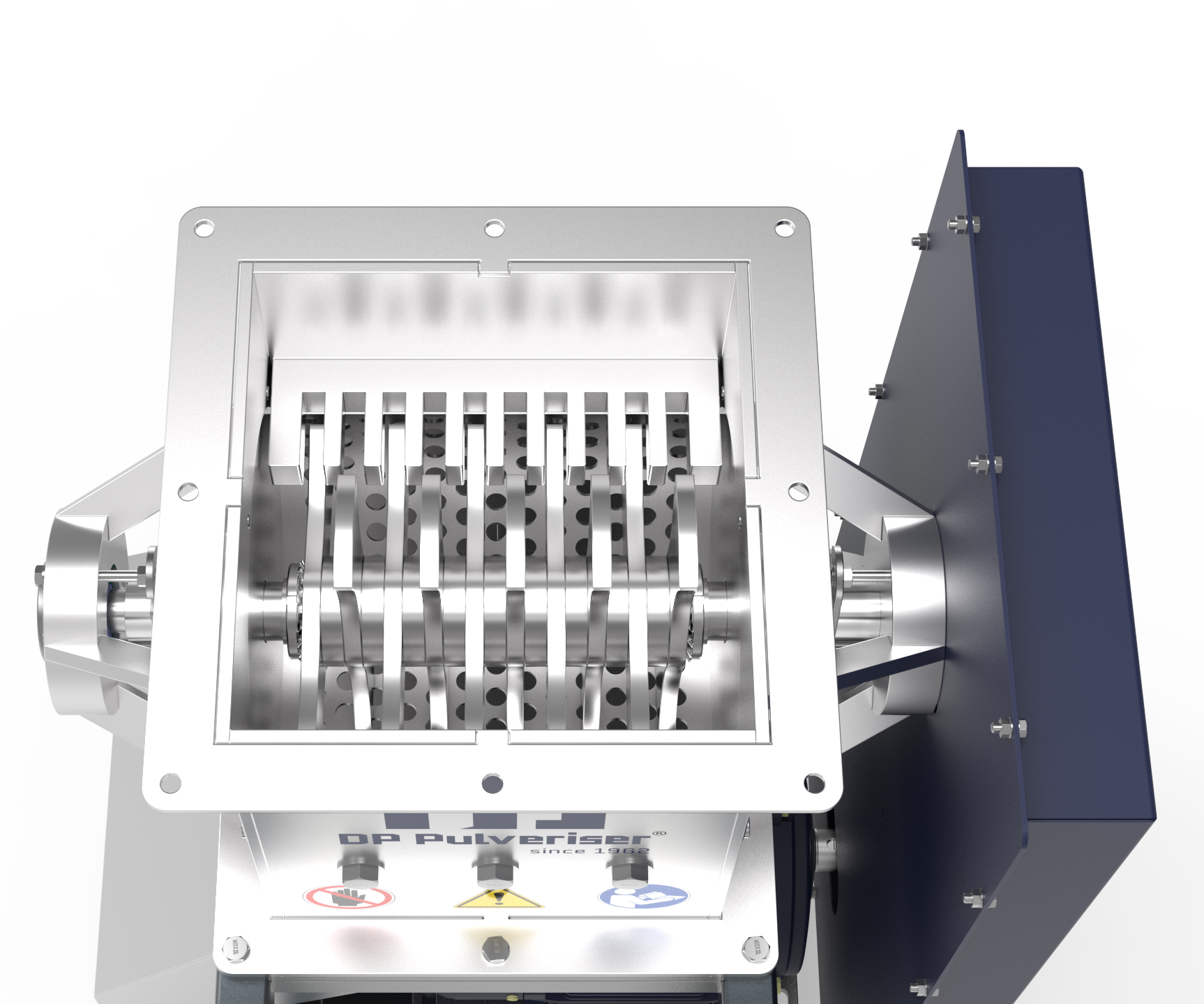

Inside the grinding chamber, the bar turbo rotor (3) is fitted with multiple bars (5) that accelerate particles toward the liner and screen (4). The material is first broken down on impact with the bars, then further reduced by repeated contact and compression between the rotating bars and the fixed liner. The screen ensures only particles of the desired size pass through.

This system is suitable for brittle to tough-elastic materials, delivering precise and consistent output. The final product, along with process air, exits via the fine product & air outlet (7) for gravity discharge collection or pneumatic conveying. Particle size can be controlled by selecting the appropriate screen opening, rotor speed, and feed rate to suit specific application requirements.

Features & Benefits

- Interchangeable bar blades allow use of both edges, extending service life and reducing maintenance costs.

- Optimized design for cooler operation and protection of heat-sensitive materials.

- Variable speed rotor drive for precise control of fineness and throughput.

- Operates efficiently with low energy consumption and reduced operating costs.

- Uniform output size ensured by close-tolerance grinding zone and screen assembly.

- Consistent performance with screen and liner design ensuring uniform output.

- Grinding chamber and components designed for easy access and quick cleaning.